As energy costs and consciousness increase, manufacturers are looking for ways to make their equipment more efficient. This also aids in compliance with energy initiatives and incentives. As this focus grows, the manufacturers are able to bridge the gap in the “comfort vs. cost” debate that many businesses face. As manufacturers have increased their focus on equipment that is efficient and effective, installers have seen an increase in ECMs standard on air side HVAC equipment. ECMs, or Electronically Commutated Motors, are motors that will vary their RPM to respond to changes in torque, in an effort to maintain a programmed setpoint, such as, static pressure, refrigerant head pressure, etc. Similar to cruise control on a vehicle, ECMs work to maintain a constant setting by varying the rotational torque (and subsequently, energy cost) of the equipment. Just as a vehicle will increase or decrease driveshaft rotations to maintain a constant speed, an ECM will speed up or slow down a unit’s fan to maintain a preset pressure setting. These predetermined levels can be manipulated by a Buildings Automation System to achieve optimum air flow within a building.

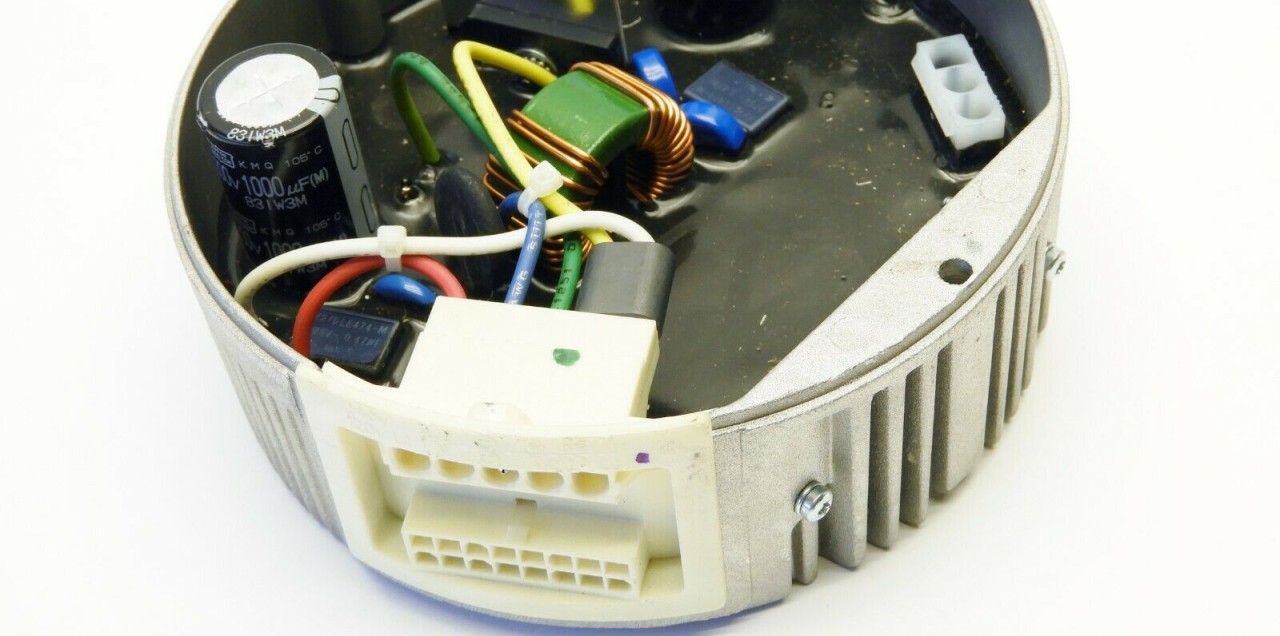

In order to achieve peak efficiency, an ECM relies on an onboard microprocessor. The microprocessor will control the amount of power sent to the motor’s electrical current generator. Like most microprocessor based motors, an ECM will generate an internal magnetic field that will cause the rotor to spin, however, unlike the others; an ECM can more precisely control the magnetic field to reduce lost energy. The reduction in energy can mean a variety of savings for any sized building.

ECM’s typically have an efficiency rating 1.5 to 2 times that of a traditional permanent split capacitor (PSC) motor, and can have almost double the life expectancy of that same PSC. The ECMs are also easier and cheaper to maintain. Improvements to mechanics include utilizing ball bearings and gradual starts and stops to prevent motor deterioration and overheating.

Electronically Commutated Motors can be great alternative when Variable Frequency Drives would not be cost effective. To find out more about ECMs, or to see if your equipment could benefit from an ECM retrofit, contact us today!

636-680-2100 or www.intfs.com