6 Steps to Take Before The Project Starts to Save the Budget and Timeline

Because of the complexity and rigid requirements of industrial facilities, our clients appreciate the breadth and depth of IFS’ services.

From highly regulated pharmaceutical facilities to chemical production lines and more.

We understand that safety and speed are two critical drivers of all industrial projects.

Safety: Safety and environmental requirements are usually strict and rigorous. We use the same experienced technicians as much as possible for a facility and have the in-house capability for high-purity orbitally welded piping and specialty resin piping.

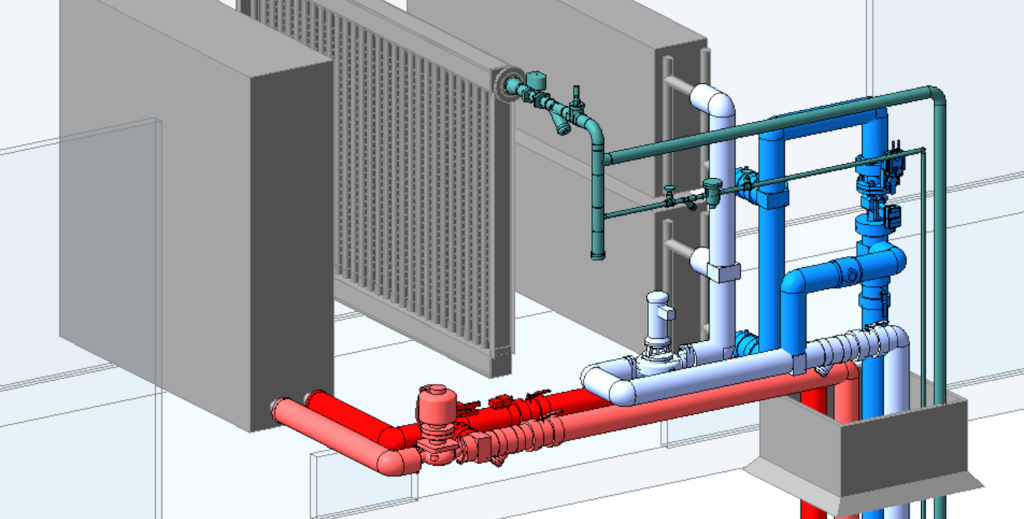

Speed: Industrial clients often are in a race to get a new process or product to market. They need a reliable, quick timeline and quick response for service issues because downtime means money lost. We spend the time in advance with computerized 3-D and isometric hand drawings to help clients visualize flat engineering designs so it is built right, the first time.

As a true partner, we listen, we strategize, we offer solutions and we deliver responsive service.

IFS builds and maintains compliant, dependable systems for all types of industrial facilities throughout St. Louis and Mid Missouri from our Columbia office.

“They’re there in a heartbeat, they have 24-hour cars. It’s a one-stop shop. Working with a one-stop shop is the only way to go.” – David Petelik, Huvepharma Inc

Over time, many industrial clients expand IFS’ role to managing nearly every aspect of their facility systems — from HVAC projects and service to plumbing, fire protection, building controls and more.

Uncommon in the St. Louis and Mid-Missouri markets — IFS’ resources match the largest mechanical firms but with the relationship focus of smaller firms.

IFS provides personal attention through a central industrial specialist — Jerry or Anthony — who gets to know the facility and keeps as many of the same technicians on projects as possible.

Clients have access to specialized departments and IFS’ engineering team for advanced services and consulting.

“IFS has the resources to do what needs to be done and done right,” said Petelik.

From new construction of high-purity production lines to retrofits and servicing facility systems, IFS builds and maintains dependable and compliant systems for industrial and pharmaceutical facilities: